Smart Innovations in Lightweighting

Hybrid Monocoque

Automotive Door Module

SMC Reinforcement

E-Rotor Sleeve

Battery Pack Separator

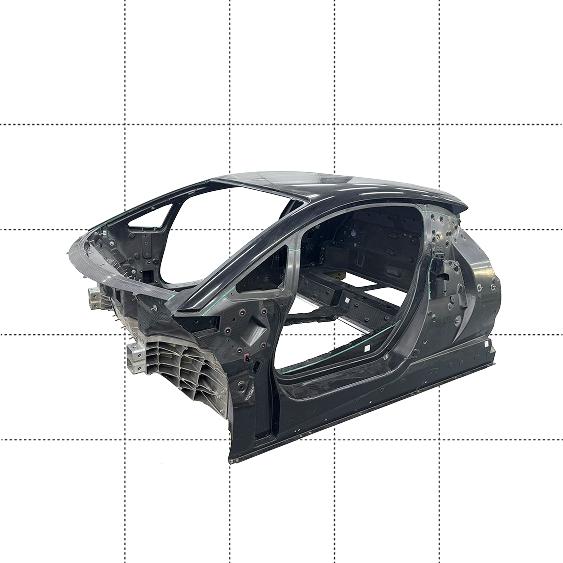

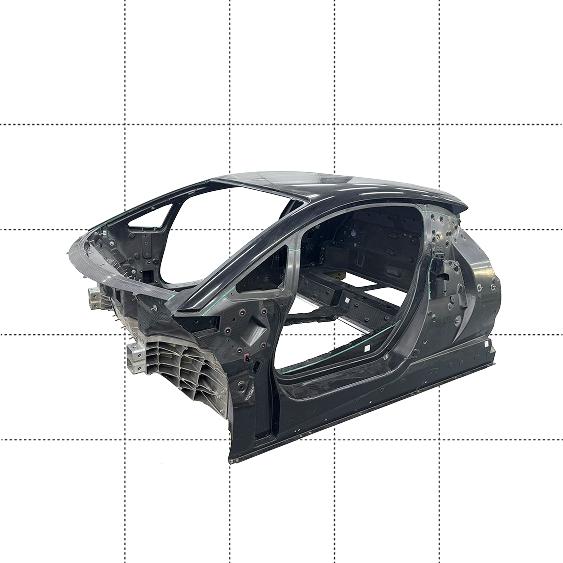

Hybrid Monocoque

Material

Carbon fiber composites, core material, steel and aluminium

Lightweight Index

0.95

Highlights

Lightweight, solid, featuring multi-part integration, and more – this Hybrid Monocoque was joint-designed and manufactured by HRC.The primary component was made using an autoclave, combined with other parts integrating into the chamber via multi-joining techniques.Special designs targeting section structures ensure its overall performance.

Automotive Door Module

Material

CF Organosheet + PP-GF pellet

Process

Overmolding

Highlights

One-step, fully automated molding, no secondary bonding required.Ultra-fast cycle times (as low as 3 minutes) with high product consistency.

SMC Reinforcement

Material

C-SMC

Process

SMC molding

Highlights

Achieves upto 45% weight reduction compared to traditional sheet metal.Enhances structural performance with a significant higher first natural frequency, improving durability, stiffness and strength.

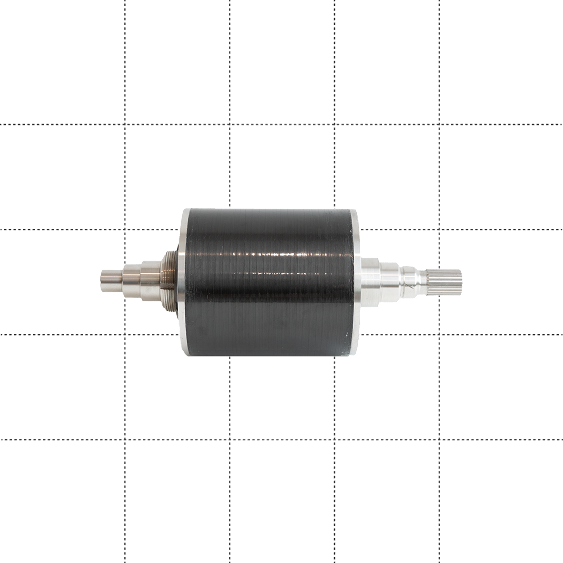

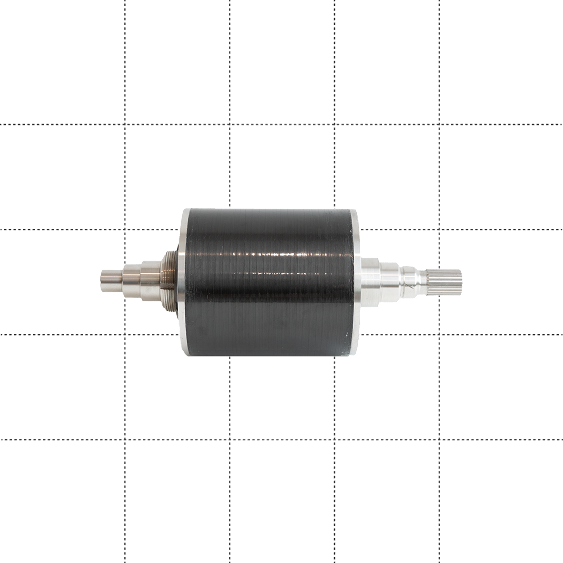

E-Rotor Sleeve

Material

CFRP + Resin

Process

Filament winding

Highlights

Carbon fiber sleeve enhances motor performance by increasing maximum speed and improving energy conversion efficiency.Lightweight design reduces motor weight, ideal for high-performance new energy vehicle motors.

Battery Pack Separator

Material

CFRP

Process

SMC & Prepreg molding

Highlights

SMC separators provide local reinforcement for battery packs.Ensures reliable preload and stability within the battery assemblies.