Stylish Composites Excellence

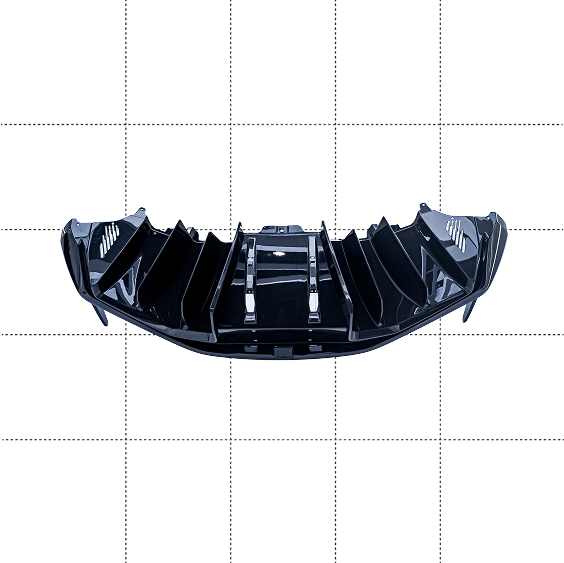

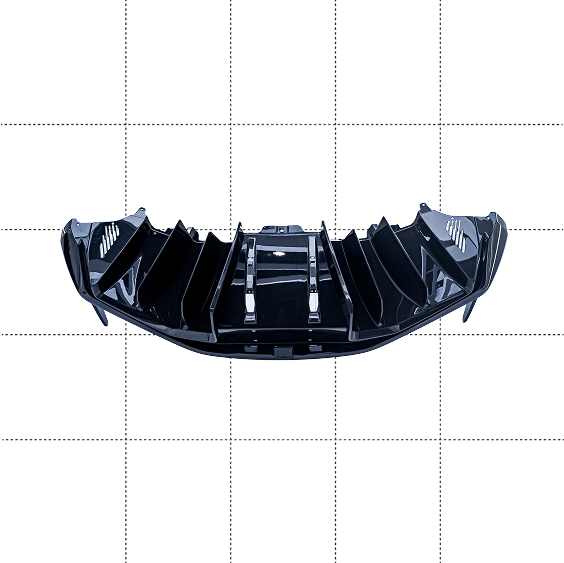

Rear Bumper Lower Trim Panel

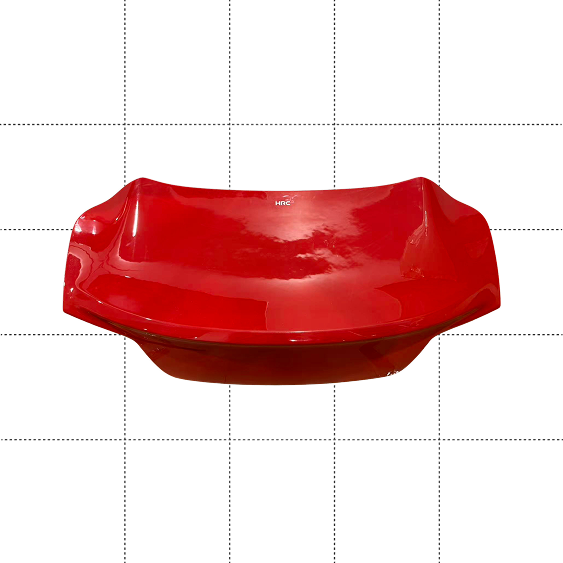

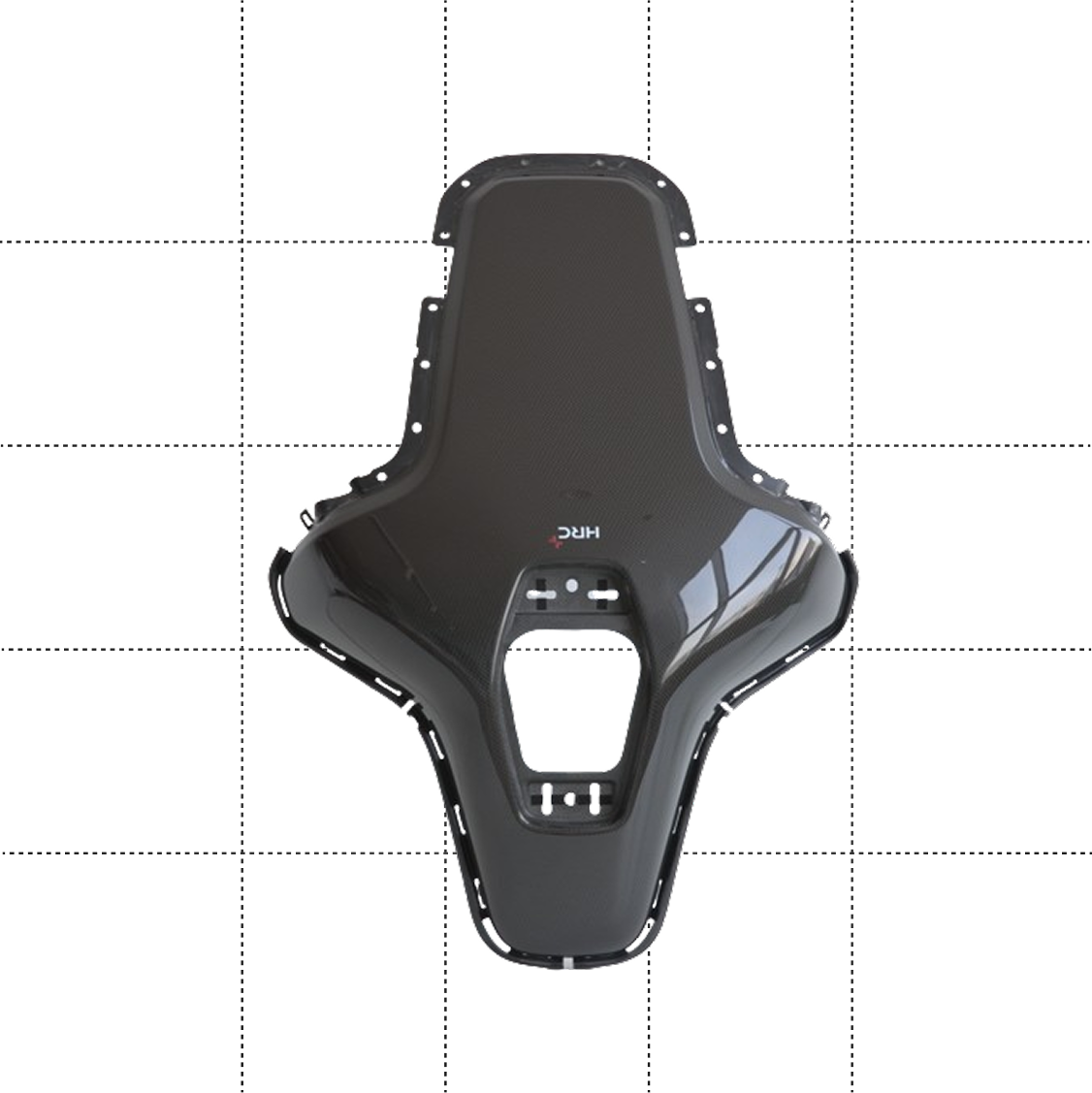

SMC Rear Tailgate

Wheel Insert

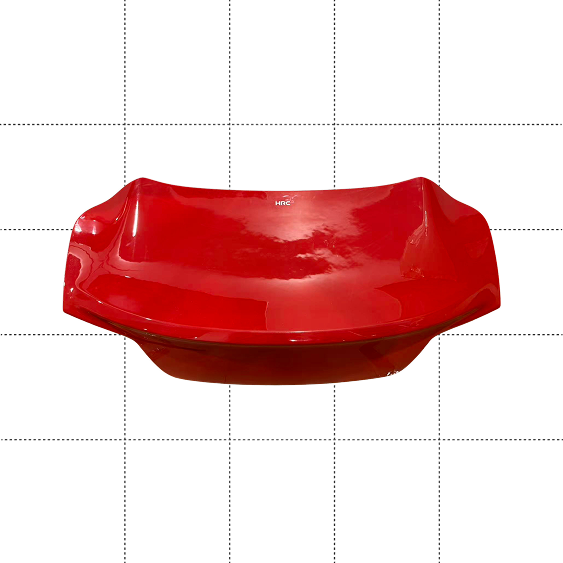

CNSL Decoration - A

CNSL Decoration - B

Backrest

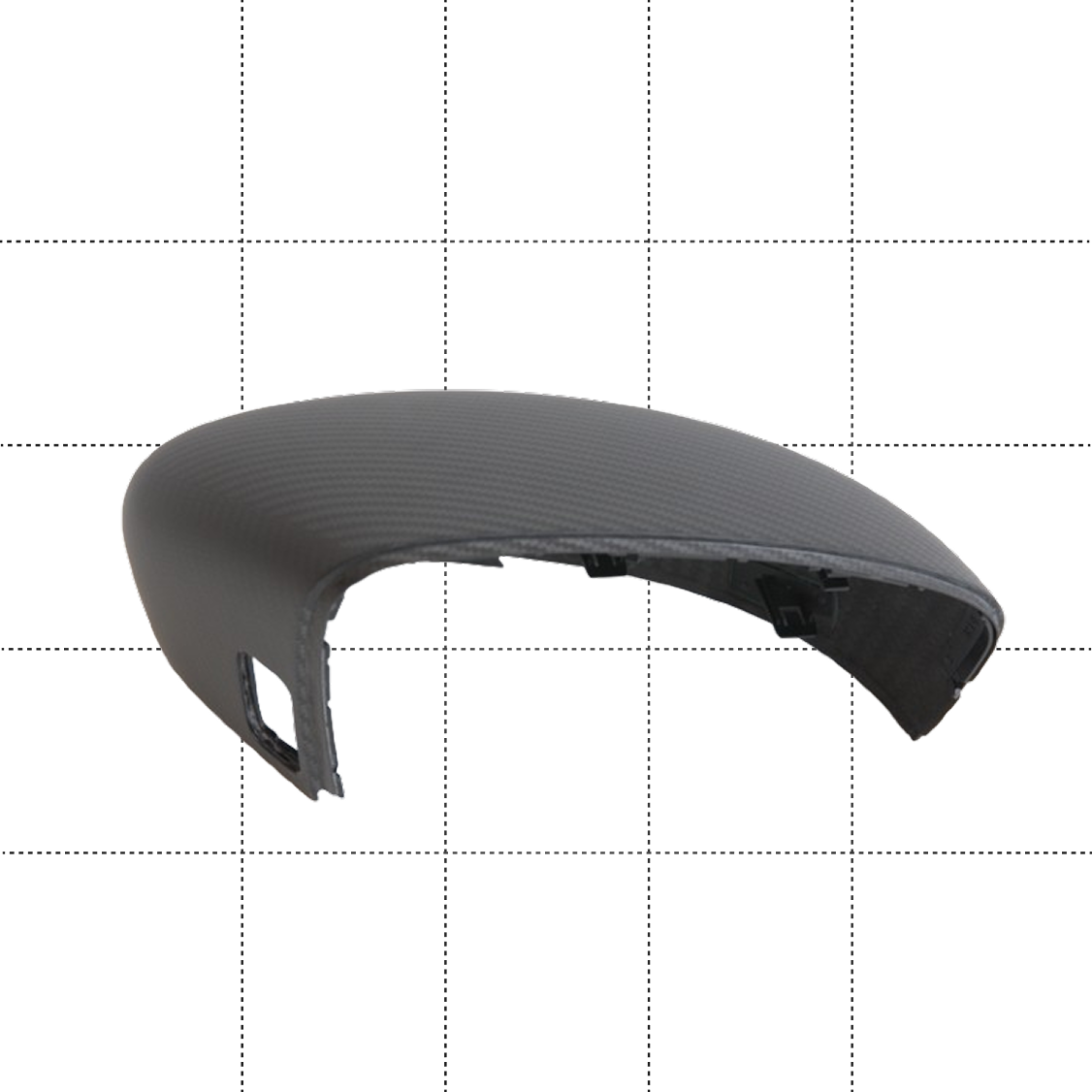

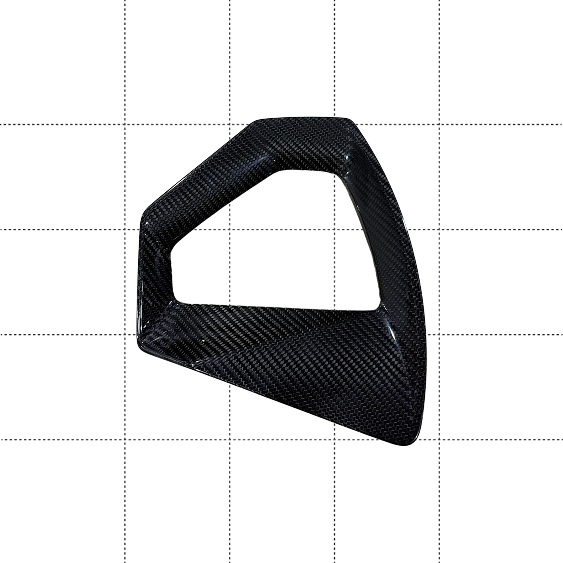

Steering Wheel Decoration

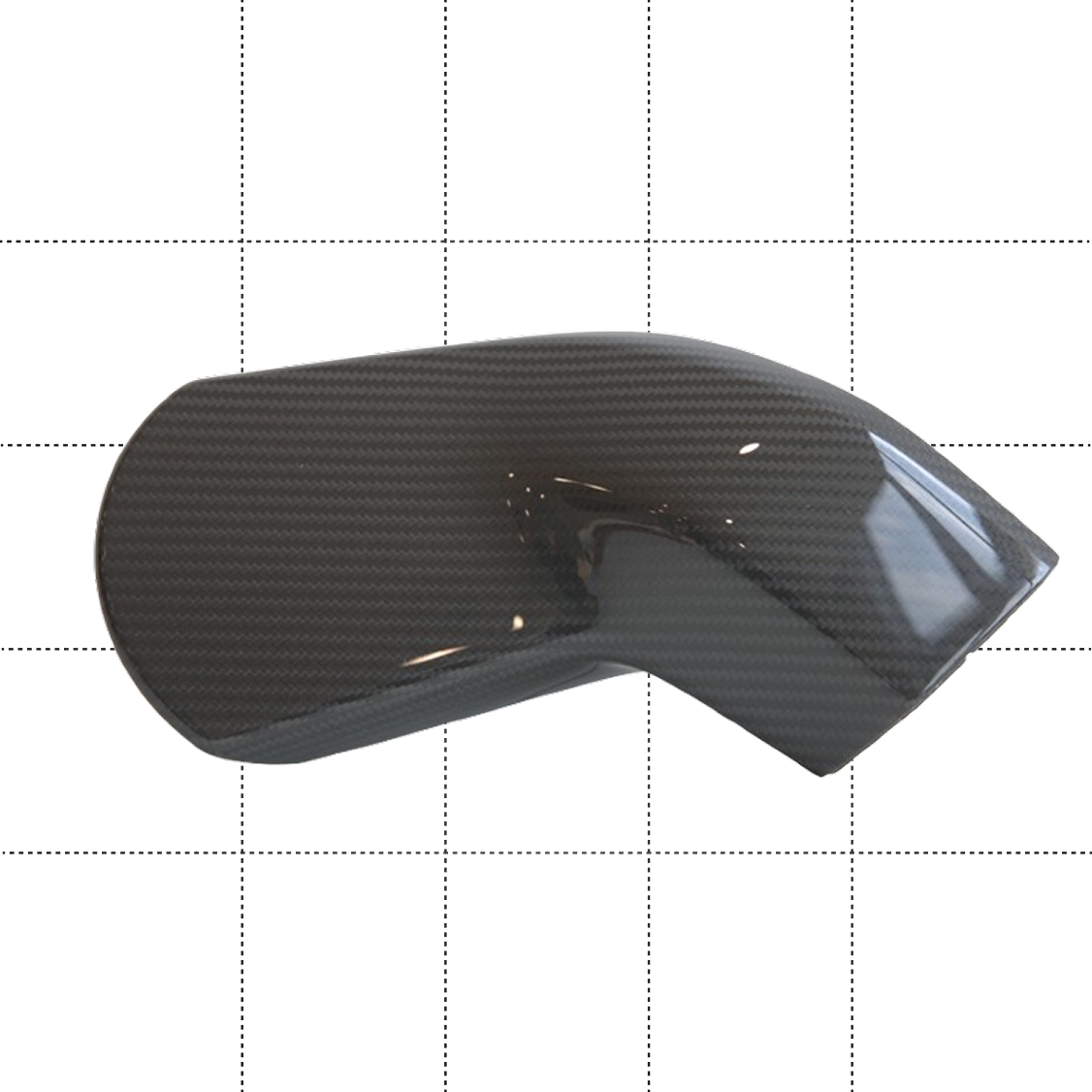

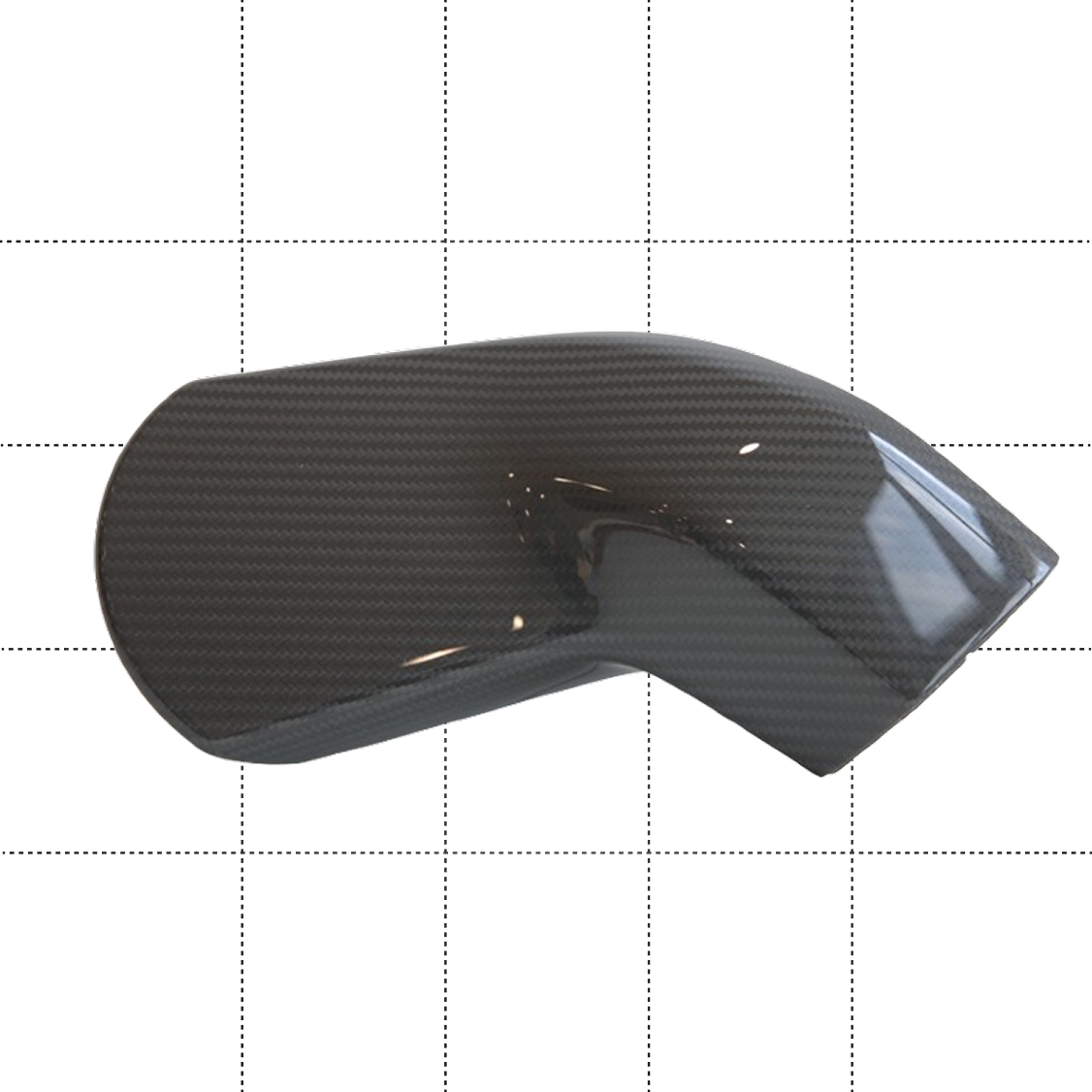

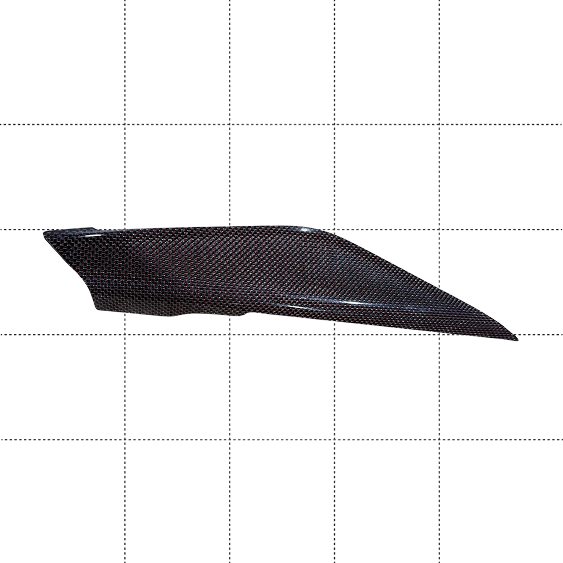

Rear View Mirror

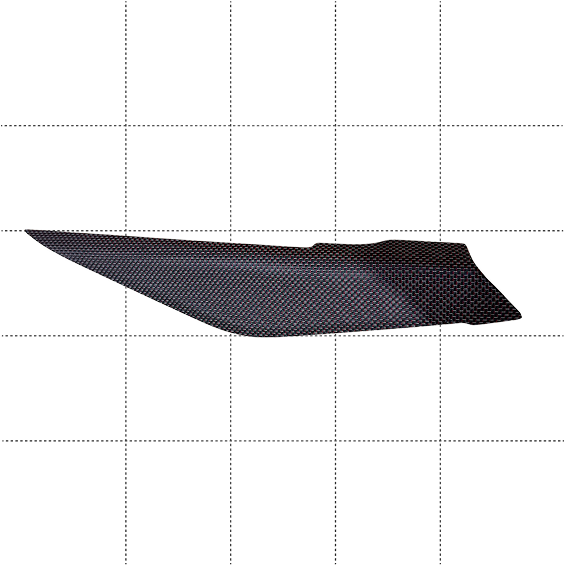

Streaming Mirror

Rear Bumper Lower Trim Panel

Material

CFRP + PC/ABS

Process

Autoclave

Highlights

Designed for supercar from carbon fiber prepreg through autoclave molding, bonded into a single piece using a high-performance structural adhesive.It lowers vehicle's body weight, decrease its center of gravity, and improve vehicle handling stability, therefore- making the vehicle safer and more stable.

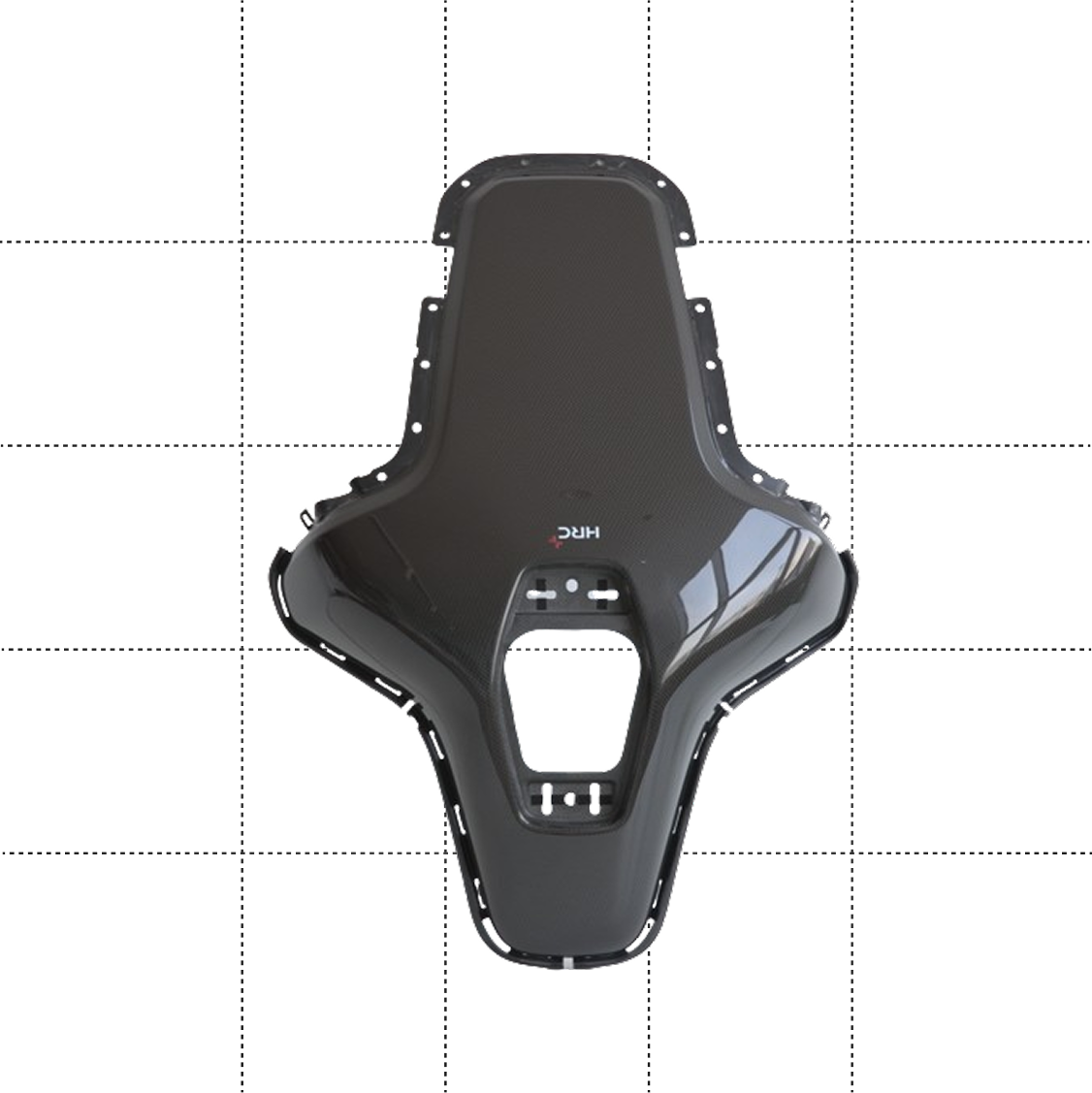

SMC Rear Tailgate

Material

C-SMC

Process

SMC molding

Highlights

Lightweight, high-strength C-SMC tailgate with 25% weight savings over traditional metal counterparts.Mass-produced by HRC with in-line bonding, assembly, and painting for a sleek , stylish design.

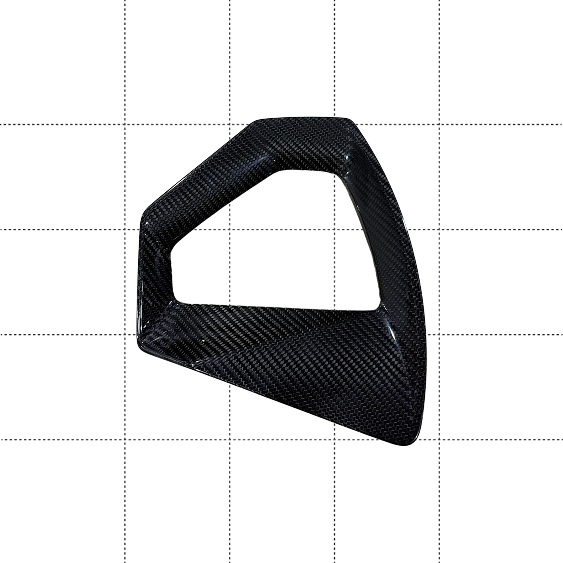

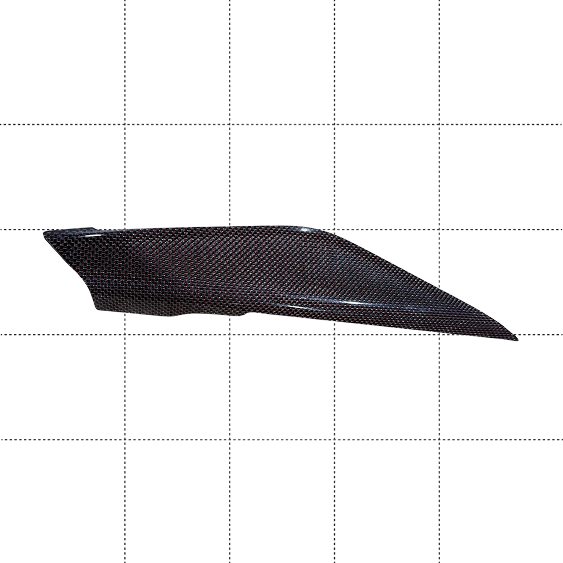

Wheel Insert

Material

CFRP

Process

Autoclave

Highlights

Provides superior rigidity and strength compared to plastic components.Optimizes airflow to enhance acceleration and brake cooling in high-speed applications such as race cars.

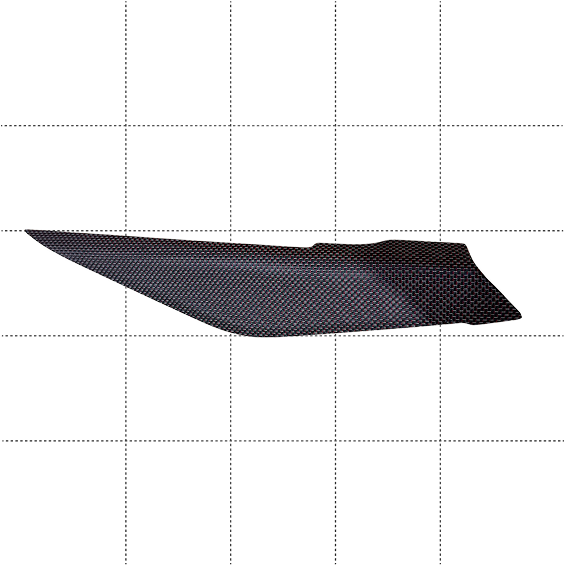

CNSL Decoration - A

Material

Compression molding + Overmolding + PUR in-mold spraying

Process

Compression Molding + Overmolding + Pur in-mold Spraying

Highlights

Lower cost and shorter cycle time compared to traditional thermoset processes.Efficient production cycles with recyclable materials.PUR in-mold spraying ideal for automotive interior applications.

CNSL Decoration - B

Material

Compression molding + Overmolding + Open pore

Process

Compression Molding + Overmolding + Open Pore

Highlights

Lower cost, high efficiency, and recyclable with reduced pre-spraying time.High spray pass rate with carbon fiber texture and tactile finish.

Backrest

Material

CFRP

Process

Autoclave

Highlights

The product is manufactured using high-strength carbon fiber prepreg and formed through an autoclave process, then bonded with plastic fasteners.It offers significant aesthetic value while reducing component weight.Additionally, it effectively absorbs impact energy during automotive collisions, substantially enhancing passenger safety.

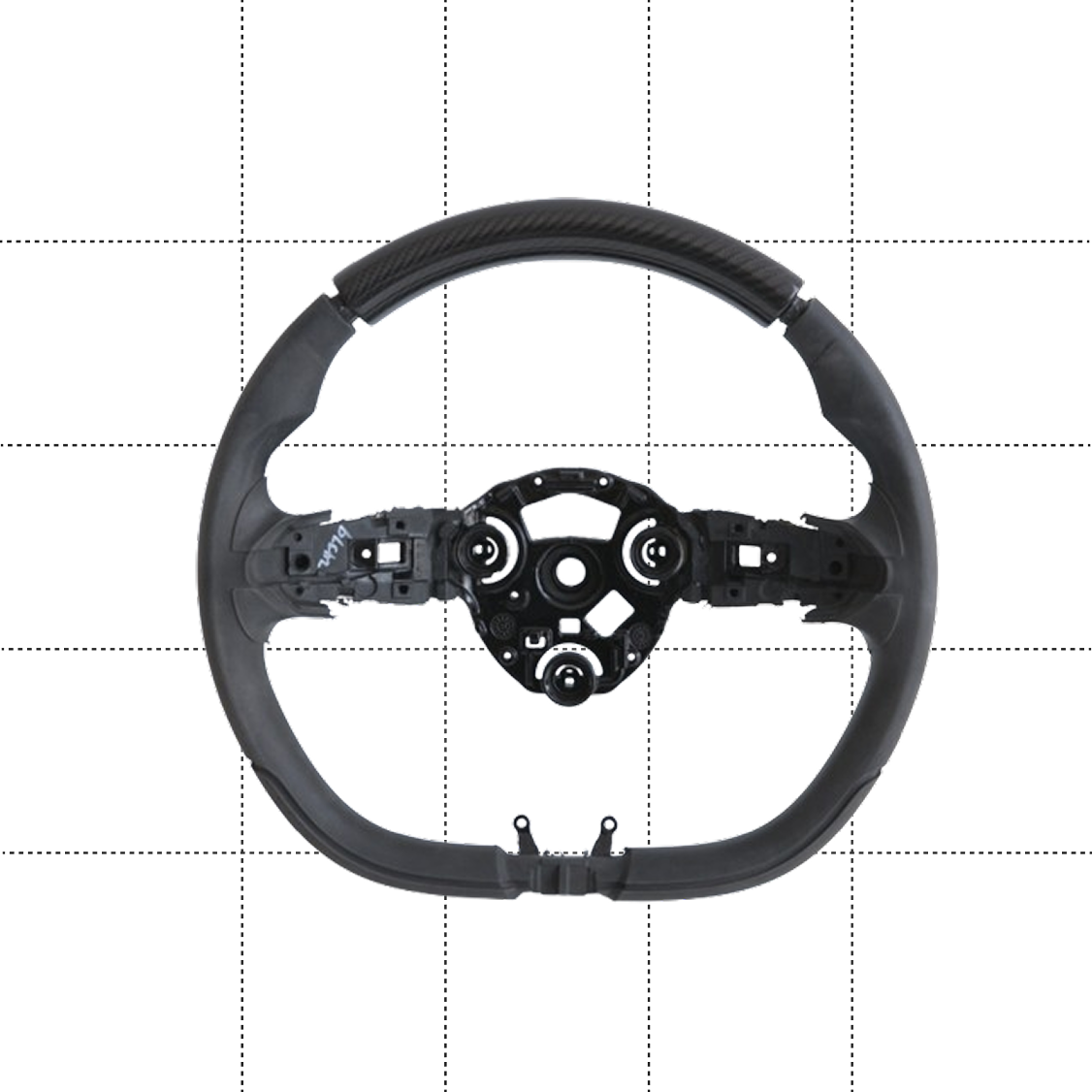

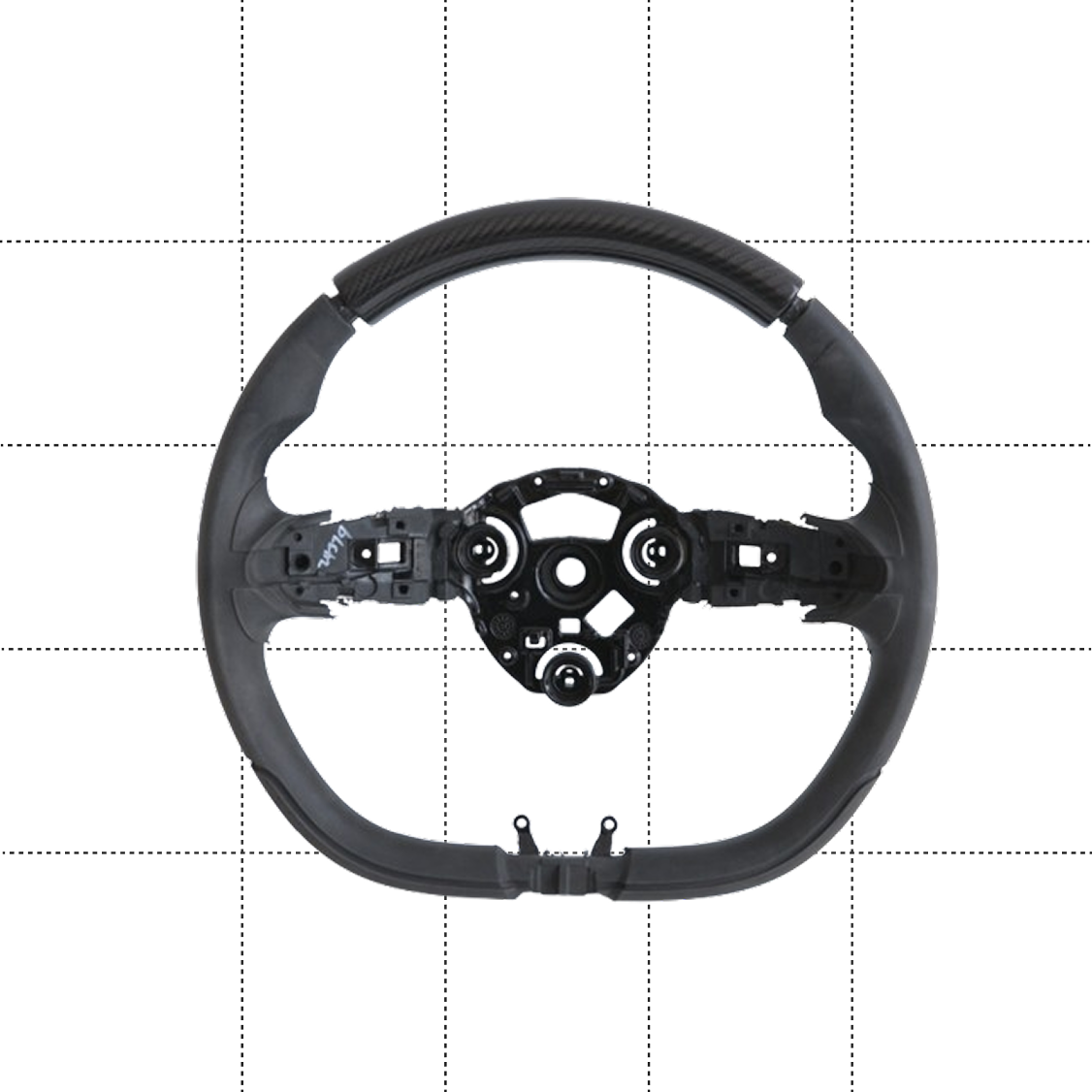

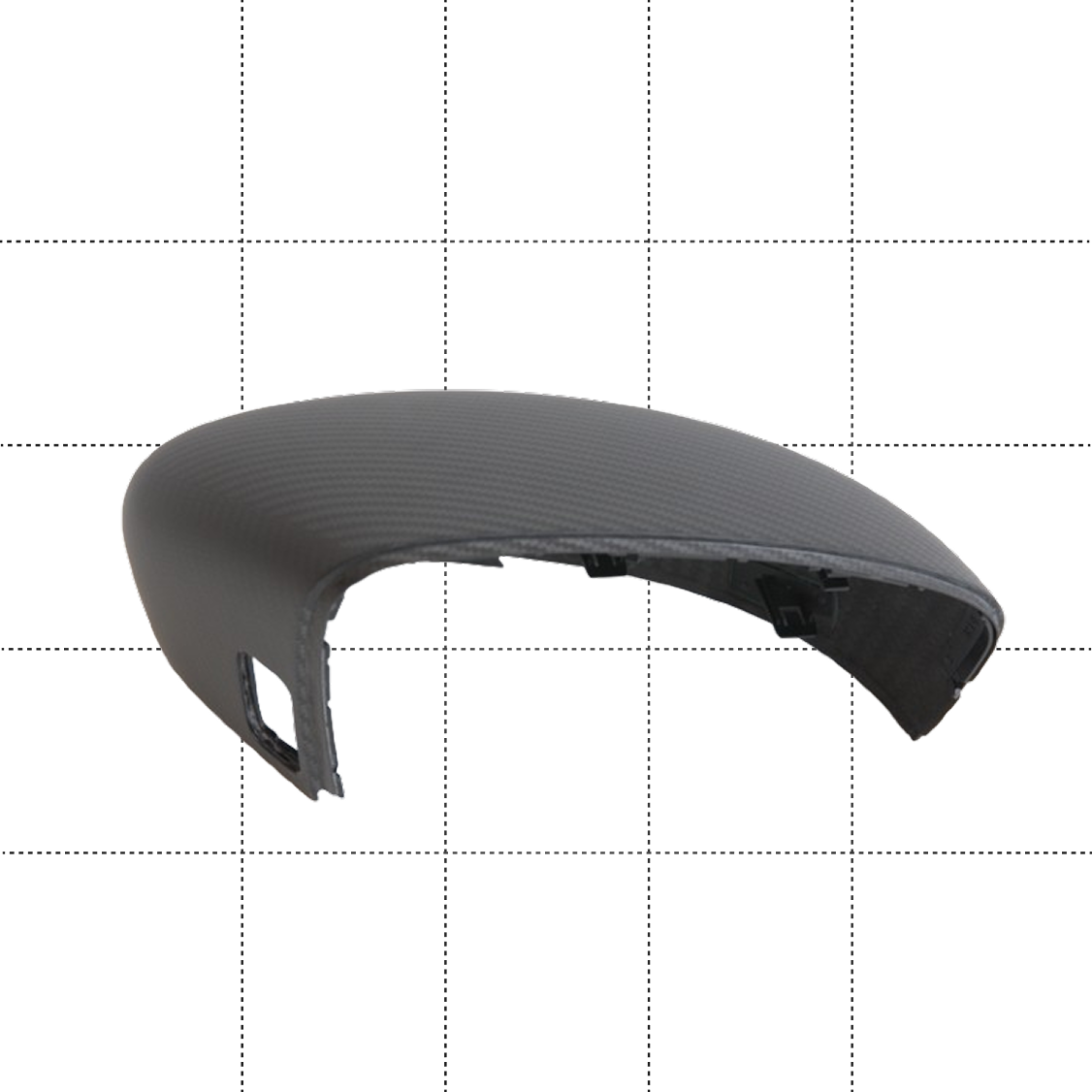

Steering Wheel Decoration

Material

CFRP

Process

PCM

Highlights

The product features an exquisite appearance and high dimensional accuracy.Meanwhile, the carbon fiber kit enhances visual appeal and improves the user experience.It offers excellent corrosion resistance, aging resistance, superior tactile feel, and outstanding thermal stability, enhancing the driver's sense of control.

Rear View Mirror

Material

CFRP

Process

Autoclave

Highlights

Strength, rigidity, and impact resistance are enhanced; weather resistance is improved, and service life is extended.

Streaming Mirror

Material

CFRP

Process

Autoclave

Highlights

Strength, rigidity, and impact resistance are enhanced; weather resistance is improved, and service life is extended.